- Reservoir Monitoring

- Production Optimization

- Fiber Optics

- Services

- About

- News

- Resources

- Careers

- Contact

Reservoir Monitoring

Production Optimization

Fiber Optics

Services

About

News

Resources

Careers

Contact

“It’s a new invention. Never been done before,” shares Gerry Chalifoux, President and CEO of Petrospec Engineering Inc. “Although conceived about fifteen years ago, the detailed design started about two years ago on our DSVD™ bitumen recovery process, which doesn’t need steam. Now we’re constructing a 3D physical model to emulate the process, and getting ready to operate the apparatus.”

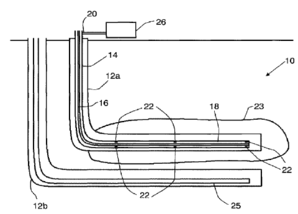

Dispersed Solvent-Vapor Drainage (DSVD™) featuring Dimethyl Ether (DME) involves Petrospec’s patented electric in-situ solvent vaporization tool with reservoir temperature maintenance (RTM) wells. Compared to hydrocarbon solvents combined with steam, this technology provides superior economic, environmental, and operational performance improvements, resulting in a zero-emissions process by virtue of utilizing CO2.

By blending DME with water, the Petrospec team can envision a low-cost hydrogen future and the opportunities that offers us on a global scale. For example, the hydrogen produced by their micro-reactor uses a DME/water blend as fuel, which may be used to supply a fuel cell in an electric vehicle, or hydrogen-powered turbine engines in aircrafts.

They will conduct three experiments at different temperatures and pressures, with results collected and utilized to history-match with a numerical model created by the University of Texas at Austin. Petrospec has partnered with a major SAGD operator to fund this project. Both the University of Texas at Austin and PERM Inc are strategic service providers and consultants on the project. “The ultimate goal is to have a tuned numerical model that can be used to evaluate a field scale pilot,” shares Chalifoux.

Martin Danesik and Noah Wiggins have been working alongside Chalifoux to design the 3D physical model and support the design and construction of the apparatus. “I feel lucky to be part of this cutting-edge project,” shared Danesik. “Our entire team, regardless of experience level, is learning new things as we work through the design process.” Their goal is to complete the project by May 2025.

Over the last two decades, companies have been working on refining existing technologies, mainly because of economic constraints. “In 2015, there were a whopping 43 companies operating SAGD projects. Today, there are only 19. The turn-around over the last few years has been really exciting though, and we’re breaking new ground again within the energy technology sphere,” Chalifoux said.

Petrospec’s sustainability portfolio includes products and services that reduce their customers’ greenhouse gas emissions while continuing to drive performance, reliability, and efficiency. Over the past year, Petrospec has moved the needle on both DSVD™ and their Power-Tube™ solution. These technologies improve their customers’ overall operational performance today while creating a viable path towards a carbon-free tomorrow.

About Petrospec Engineering

Established in 1997, Petrospec is proud to be a leading provider of turn-key reservoir monitoring systems for oil and gas operators. We strive to improve efficiency, meet high safety standards, and provide equipment and software for harsh environments. Our Edmonton-based company is a global innovator in downhole instrumentation, production optimization, and the accurate measurement of temperature, pressure, acoustics, and flow.

Back to news